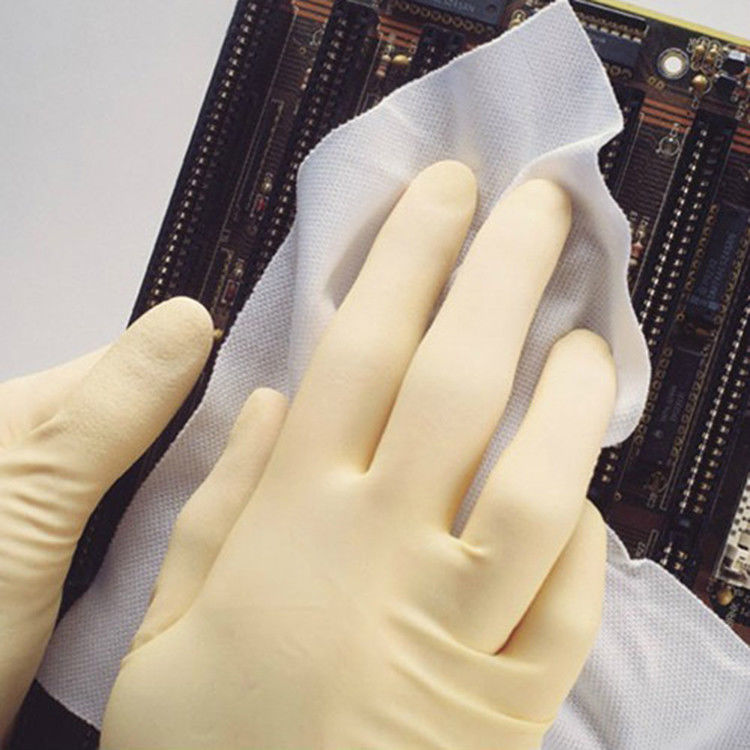

Lint Free Disposable Cleanroom IPA Wipes White Industrial 100 Polyester Sterile Presaturated Wipes

-

Highlight

Lint Free cleanroom ipa wipes

,Disposable cleanroom ipa wipes

,Polyester sterile presaturated wipes

-

Sheet Size20*20cm

-

WeightWeight

-

Package StyleRefill Pack/ Plastic Fliptop / Tub

-

Packing1pcs/10pcs/25pcs/40pcs/80pcs

-

SampleFree, Welcome To Get The Free Samples From Us

-

OEMAccept OEM

-

ColorWhite

-

UsageCleaning Usage,Cleanroom Protection,Electronics Semiconductor Industry Ect

-

ApplicationCleanroom,Electronic

-

LogoCustomised Logo Is Available

-

TypeLint-free Cleanroom Wiper

-

Place of OriginChina

-

Brand NameMyesde

-

CertificationTDS ROHS

-

Minimum Order Quantity10Bags

-

Delivery Time5-8 work days

-

Payment TermsD/A, L/C, D/P,T/T, Western Union, MoneyGram

-

Supply Ability1000Bags/Month

Lint Free Disposable Cleanroom IPA Wipes White Industrial 100 Polyester Sterile Presaturated Wipes

Sealed Edge Laundered Polyester 70% IPA - Sterile Knit Wet Cleanroom Wiper

Product Detail:

Presaturated wipes ensure consistent saturation of each wipe independent of operator. Presaturated wipes can increase solvent control and accountability as well as reduce VOC emissions. The wipes are provided in convenient and easy to use peel and reseal pouches.

Benefits:

1.Packaged in easy-to-use, recloseable slider bags reducing solution evaporation that preserves the consistent wiper wetness level

2.Low levels of ions, NVRs (non-volatile residues), particles, and fibers for use in critical cleaning applications

3.Meets USP <797> and USP <800> wiper requirements

Technical Data:

| Attribute; (units) | Value ** | Test Method | ||

| Basis weight; nominal (g/m2) | 120 | MSD-QI-QS-007 A0 | ||

| Absorbency in water | IEST-RP-CC004.3 | |||

| Intrinsic; (mL/g) | 2.41 | |||

| Extrinsic; (mL/m2) | 290 | |||

| Sorptive rate; (seconds) | 1 | IEST-RP-CC004.3 | ||

| Non-volatile residue, NVR | IEST-RP-CC004.3 | |||

| In deionized water; (g/m2) | 0.014 | |||

| In isopropanol; (g/m2) | 0.012 | |||

| Specific ions | IEST-RP-CC004.3 | |||

| Sodium; (ppm) | 0.025 | |||

| Chloride; (ppm) | 0.076 | |||

| Potassium; (ppm) | 0.094 | |||

| Particles, readily releasable | ||||

| APC: ≥0.3μm(Ea/ft3) | 92 | IEST-RP-CC003.3 | ||

| LPC:≥0.5μm(106/m2 ) | 16 | IEST-RP-CC004.3 | ||

Material:

• 100% Polyester

• Microfiber(70%Polyester and 30% Nylon)

• 100% Melt-blown fabric(PP)

• 55%Woodpulp and 45% Polyester

Technical Data:

The data is based on the polyester material.

Shelf Life:

• Non-Sterile (Dry) –3 years from date of manufacture

• Non-Sterile (Pre-Wetted) – 2 years from the date of manufacture

• Sterile – 2 years from the date of manufactue

Features:

1.Pre wetted wiper can control the amount of solvent released on the surface of the object,in line with the requirements of wiping;

2.It can reduce the amount of solvent and its evaporation,so that the solvent is controllable;

3.Healthier and safer working environment,reduce the release of volatile organic compounds, greatly reduce environmental pollution;

4.It can reduce the fire and its potential harm caused by solvent leakage

5.Reduce the generation of particles and fibers, reduce in the spray painting, sealing, welding, paint construction of defective products, so that the wiping process is more standardized, eliminate the replacement of operators, bring aboutthe uncertainty of product quality control, greatly reduce the cross pollution in the process of cleaning.

![]()