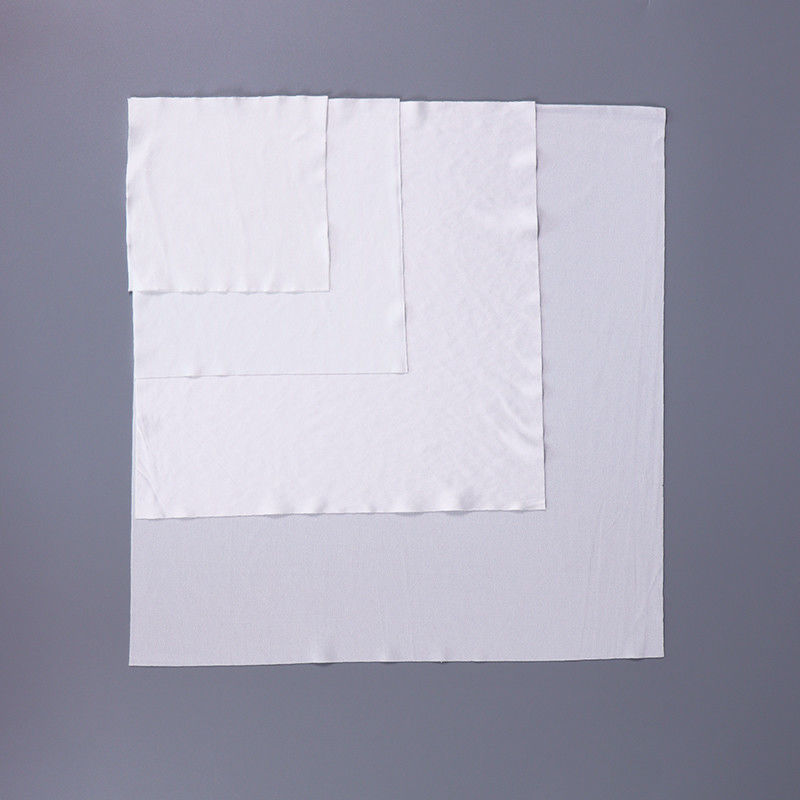

Promotional 180gsm 9x9inch Laser Cut Industrial Microfiber 100 Class Cleanroom Wiper

-

Highlight

9x9inch Cleanroom Wiper

,180gsm Cleanroom Wiper

,Industrial Microfiber Cleanroom Wiper

-

Weight180g/m2

-

Size9'' X 9"

-

Cutting WayLaser Cut

-

Packing100pcs/bag,10bags/ctn

-

LogoCustomised Logo Is Available

-

Laundered MethodBy 18MΩ Ultra Clean Water

-

Usage IndustryCleanroom,electronics Industry And Ect

-

UsageCleaning Usage,Cleanroom Protection,Oil,Semiconductors,Electronics Semiconductor Industry Ect

-

Place of OriginChina

-

Brand NameMyesde

-

CertificationROHS,TDS,MSDS

-

Model NumberMW-201-9X9

-

Minimum Order Quantity10Bags

-

Delivery Time5-8Work Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability10000Bags/month

Promotional 180gsm 9x9inch Laser Cut Industrial Microfiber 100 Class Cleanroom Wiper

Promotional 180gsm 9x9inch Laser Cut Industrial Microfiber 100 Class Cleanroom Wiper

Description:

Dust free micro-fiber cloth is knitted with 100% complete continuous micro-fiber, the four sides of wipe cloth is adopted the laser or ultrasonic sealed edge technology, it extremely prevents the fall off of fiber and produce of micro-dust.

This wiper is double-knit microfiber Cleanroom wiper.It is the cleanest,most consistent and rigorously quality tested cleanroom wiper.

Edge sealed: laser cut. narrow ultrasonic cut&wide ultrasonic cut are available

Cleanroom criteria:Class 100

Package method:Packed in Class 100 clean room,vacumn packing.

| Material | 75% polyester+25nylon |

| Color | White |

| Weight | 180g/m2±5g |

| Size | 9'' x 9" |

| Usage industry | Cleanroom,electronics industry and ect |

| Cutting way | Laser cut |

| Packing | 100pcs/bag,10bags/ctn |

| Laundered method | By 18MΩ ultra clean water |

| Logo | Customised logo is available |

| Certificate | ROHS,TDS,MSDS |

Technical Data:

Wipe material: 75% Polyester 25% Nylon

| Attribute; (units) | Value ** | Test Method | ||||

| Basis weight; nominal (g/m2) | 178 | MSD-QI-QS-007 A0 | ||||

| Absorbency in water | IEST-RP-CC004.3 | |||||

| Intrinsic; (mL/g) | 1.67 | |||||

| Extrinsic; (mL/m2) | 297.3 | |||||

| Sorptive rate; (seconds) | 1 | IEST-RP-CC004.3 | ||||

| Non-volatile residue, NVR | IEST-RP-CC004.3 | |||||

| In deionized water; (g/m2) | 0.014 | |||||

| In isopropanol; (g/m2) | 0.012 | |||||

| Specific ions | IEST-RP-CC004.3 | |||||

| Sodium; (ppm) | 0.012 | |||||

| Chloride; (ppm) | 0.096 | |||||

| Potassium; (ppm) | 0.084 | |||||

| Particles, readily releasable | ||||||

| APC: ≥0.3μm(Ea/ft3) | 24 | IEST-RP-CC003.3 | ||||

| LPC:≥0.5μm(106/m2 ) | 19 | IEST-RP-CC004.3 | ||||

Features and Benefits:

• Silk-smooth surface finish for use on even the most delicate surfaces

• Durable abrasion resistance for use when removing microcontamination from large areas and irregular surfaces

• Best-in-class fluid absorption

• Leaves a polished finish on surfaces such as stainless steel

• Available in a range of edge finishes to meet your application requirements

Applications:

• Cleaning with solvents such as isopropyl alcohol

(IPA), ethanol, , and degreasers.

• Applying and removing lubricants, adhesives, residues and other solutions including disinfectants.

Cleanroom Environment:

• ISO Class 3 – 8

• Class 1 – 100,000

Shelf Life

• Non-Sterile (Dry) – 3 years from date of manufacture

![]()

![]()

![]()