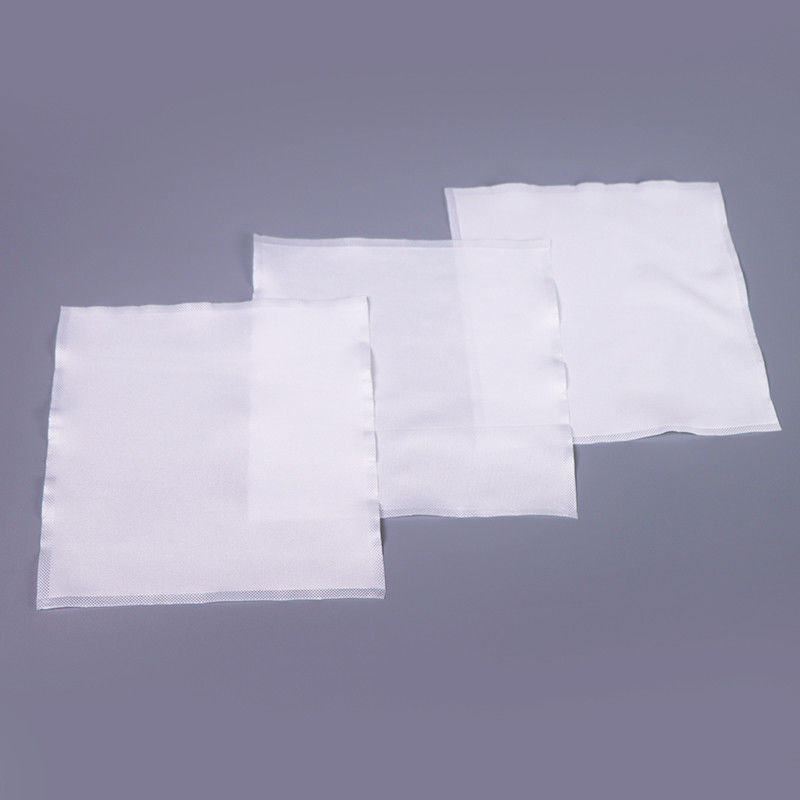

6 Inch 120gsm Polyester Cleanroom Wipes 100pcs LCD Cleaning Wipes Soft And Absorbent

-

Highlight

6 inch polyester cleanroom wipes

,120gsm polyester cleanroom wipes

,100pcs lcd cleaning wipes

-

Material100% Polyester

-

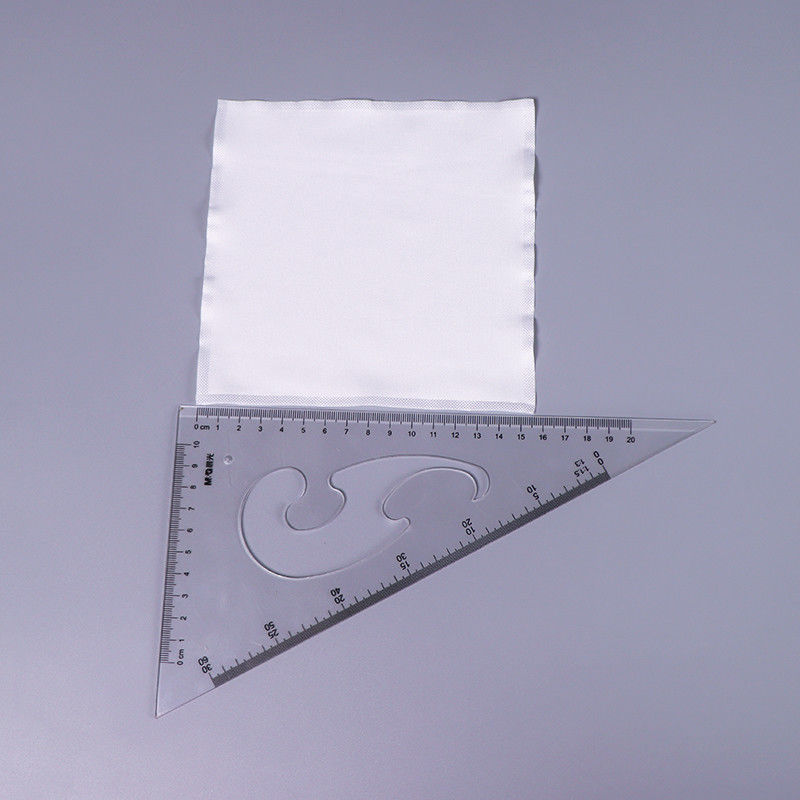

Size6'' X 6"

-

Cutting WayLaser Cut

-

Weight120g/m2

-

Usage IndustryCleanroom,Electronics Industry And Ect

-

Packing100pcs/bag,10bags/ctn

-

LogoCustomised Logo Is Available

-

Laundered MethodBy 18MΩ Ultra Clean Water

-

Place of OriginChina

-

Brand NameMyesde

-

CertificationROHS,TDS,MSDS

-

Minimum Order Quantity100Bags

-

Delivery Time5-8 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability10000Bags/month

6 Inch 120gsm Polyester Cleanroom Wipes 100pcs LCD Cleaning Wipes Soft And Absorbent

6Inch 100pcs 120Gsm 100% Polyester Cleanroom Clean Wiper Soft And Absorbent

Description:

Polyester cleanroom wipers are perfect for wiping and cleaning sufraces, equipment and parts. As well as applying and removing lubricants, adhesives, residues, and other solutions including disinfectants. Individually lot coded for ease of traceability and quality control.

Key Attributes:

• 8 times the number of filaments and 4 times the surface area of standard polyester wipers

• Ultrasonically sealed edges minimize fiber and particle generation and provide a smooth nonabrasive edge

• Laundered and packaged in an ISO Class 4 (Class 10) cleanroom

Material/Structure: 100% Polyester with a Sealed-Edge.

| Material | 100% polyester |

| Color | White |

| Weight | 120g/m2±5g |

| Size | 6'' x 6" |

| Usage industry | Cleanroom,electronics industry and ect |

| Cutting way | Laser cut |

| Packing | 100pcs/bag,10bags/ctn |

| Laundered method | By 18MΩ ultra clean water |

| Logo | Customised logo is available |

| Certificate | ROHS,TDS,MSDS |

Technical Data:

| Attribute; (units) | Value ** | Test Method | ||||

| Basis weight; nominal (g/m2) | 123 | MSD-QI-QS-007 A0 | ||||

| Absorbency in water | IEST-RP-CC004.3 | |||||

| Intrinsic; (mL/g) | 2.51 | |||||

| Extrinsic; (mL/m2) | 308.73 | |||||

| Sorptive rate; (seconds) | 1 | IEST-RP-CC004.3 | ||||

| Non-volatile residue, NVR | IEST-RP-CC004.3 | |||||

| In deionized water; (g/m2) | 0.010 | |||||

| In isopropanol; (g/m2) | 0.012 | |||||

| Specific ions | IEST-RP-CC004.3 | |||||

| Sodium; (ppm) | 0.023 | |||||

| Chloride; (ppm) | 0.081 | |||||

| Potassium; (ppm) | 0.079 | |||||

| Particles, readily releasable | ||||||

| APC: ≥0.3μm(Ea/ft3) | 86 | IEST-RP-CC003.3 | ||||

| LPC:≥0.5μm(106/m2 ) | 9 | IEST-RP-CC004.3 | ||||

Applications:

• Designed for use in ISO Class 4 (Class 10) and higher cleanroom environments

• Designed for scratch sensitive surfaces

• Used in display and semiconductor industries

• Suited for cleaning precise optical machinery and tools

• Used for cleaning a delicate process in critical cleanrooms

• Applying and removing cleaning and disinfecting solutions

Features :

• Cleanroom laundered and packaged providing ultra low levels of ions and non volatile residues.

• Designed for use on abrasive surfaces. This wipe will not easily snag or abrade releasing articles and fibers into the process or environment.

• Excellent chemical resistance for compatibility with a variety of solutions.

• Individually lot coded for ease of trace-ability and quality control.

• Good absorption with water and solvents.Hold more

dirt and residues than average wipe. Remove residues from the surface more effectively.

Benefits:

•Excellent chemical resistance for compatibility with a variety of solutions.Autoclave safe.

• Ultrafine microfiber yarn increases surface area and provides superior wiping efficiency

• Wedge shaped fiber cross section lifts, entraps and removes particulates from critical surfaces

• Cleans efficiently with less solvent usage than traditional wipers

• Removes oily soils with little or no solvent required

• Soft hand and non-abrasive ultrasonic sealed edge are excellent for sensitive or scratch prone surfaces

• Continuous filament yarns and tight knit construction provide excellent abrasion resistance and low fiber shedding

• Chemically compatible with IPA and other commonly used solvents

Cleanroom Environment:

• ISO Class 3 – 8

• Class 1 – 100,000

Shelf Life

• Non-Sterile (Dry) – 3 years from date of manufacture

• Non-Sterile (Pre-Wetted) – 2 years from the date of manufacture

• Sterile – 2 years from the date of manufacture

![]()

![]()