-

Highlight

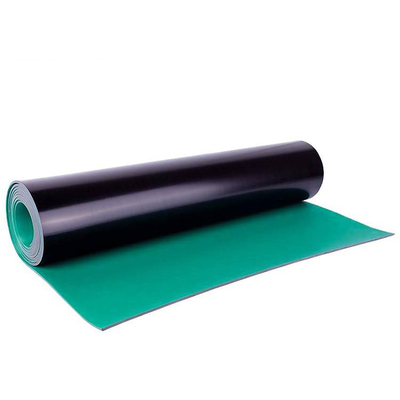

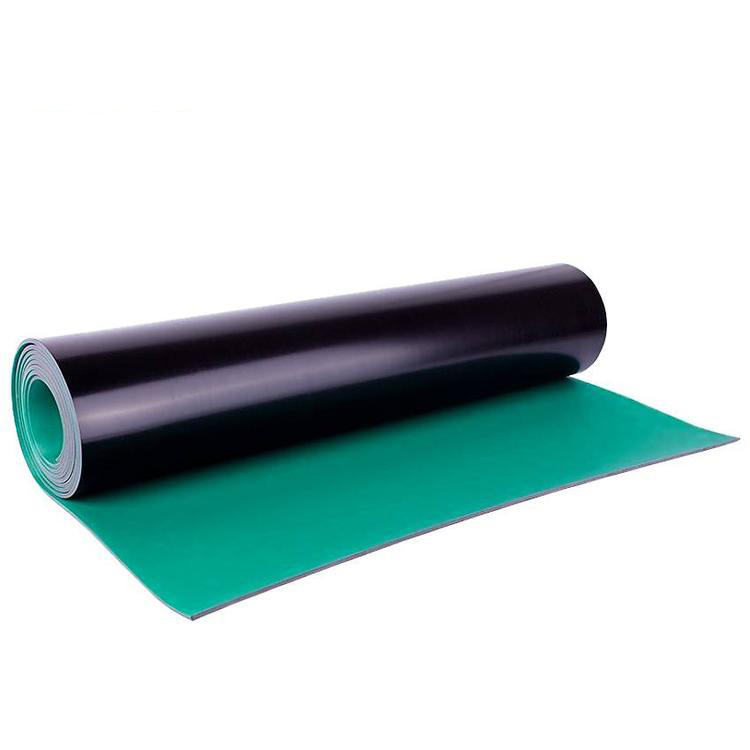

Critical Electronics Work ESD Table Mat

,Electronics Work ESD Table Mat

,ESD Table Mat

ESD Table Mat Static Safe Surface For Critical Electronics Work

Engineered for long-term performance in ESD-sensitive environments.

ESD Table Mats

Electrostatic discharge (ESD) is a silent threat in electronics assembly and precision manufacturing—a single spark as low as 100 volts can destroy integrated circuits or damage PCBs permanently.

Our ESD table mats create a controlled path for static charges to dissipate safely, ensuring compliance with ANSI/ESD S20.20 and IEC 61340 standards while protecting your production line.

Product Features

✔ Advanced 2-Layer or 3-Layer Design

– Top Layer: Static-dissipative for safe component contact

– Middle Layer: Reinforced for durability (3-layer option)

– Bottom Layer: Fully conductive for efficient grounding

✔ Outstanding ESD Performance

– Surface resistance: 10⁶–10⁹ Ω

– Compatible with wrist straps, grounding cords, and monitors

✔ Heat & Chemical Resistant Surface

– Handles soldering iron contact and cleaning solvents without degradation

✔ Long Service Life

– Resistant to curling, cracking, and hardening under continuous use

✔ Multiple Color Options

– Standard colors: Green, Blue, Gray – Improves visual workflow control

Technical Specifications

| Property | Details |

|---|---|

| Material | ESD-Safe Rubber / Vinyl |

| Layers | 2-Layer or 3-Layer Structure |

| Surface Resistance | 10⁶–10⁹ Ω |

| Thickness | 2 mm or 3 mm |

| Sizes | 24"x36" / 24"x48" / Custom |

| Compliance | ANSI/ESD S20.20, IEC 61340 |

Applications

-

Electronics Assembly Lines & PCB Workstations

-

Semiconductor & Cleanroom Production Tables

-

QA & Testing Labs

-

Service & Repair Benches

What Makes Our ESD Mats Different?

-

Designed for extended lifespan under heavy-duty use

-

Compatible with all ESD accessories (wrist straps, cords, snap kits)

-

Easy to clean and maintain for low contamination risk

-

OEM custom sizes, colors, and logos available

Installation & Maintenance Tips

-

Always connect the mat to a verified ground point using an ESD grounding cord

-

Use mat cleaner to maintain surface resistance properties

-

Inspect regularly for wear and replace if resistance exceeds standards