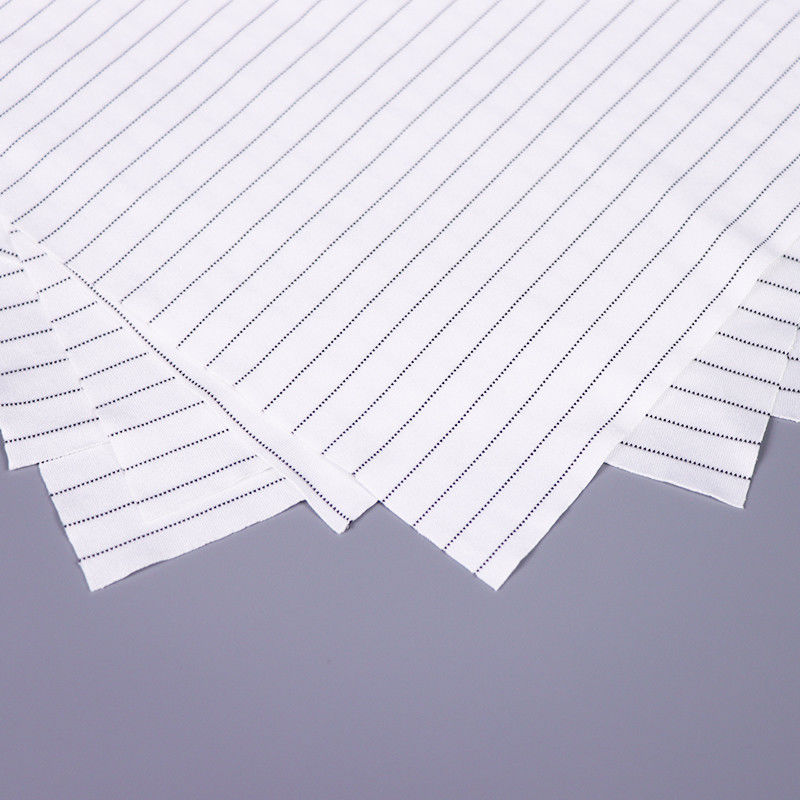

Anti Dust Industrial Antistatic Cleanroom Wipes Super Absorption Polyester Knit Wipes

-

Highlight

anti dust Antistatic Cleanroom Wipes

,Industrial Antistatic Cleanroom Wipes

,Super Absorption polyester knit wipes

-

Weight230g/m2

-

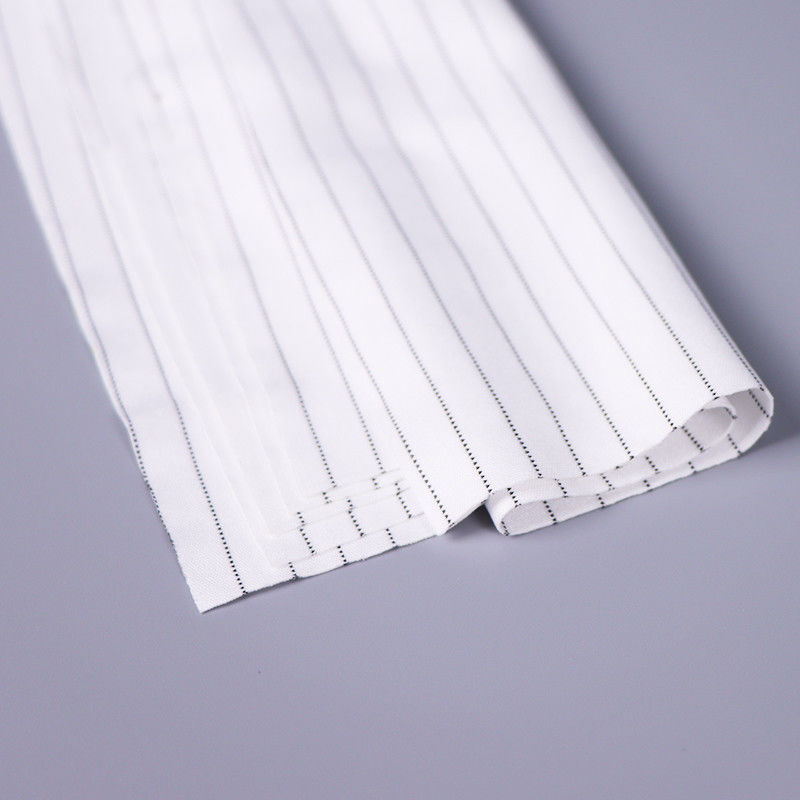

Size6'' X 6"

-

Cutting WayLaser Cut

-

Packing100pcs/bag,10bags/ctn

-

LogoCustomised Logo Is Available

-

Laundered MethodBy 18MΩ Ultra Clean Water

-

Usage IndustryCleanroom,electronics Industry And Ect

-

UsageCleaning Usage,Cleanroom Protection,Oil,Semiconductors,Electronics Semiconductor Industry Ect

-

Place of OriginChina

-

Brand NameMyesde

-

CertificationROHS,TDS,MSDS

-

Model NumberMW-201-9X9

-

Minimum Order Quantity10Bags

-

Delivery Time5-8Work Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability10000Bags/month

Anti Dust Industrial Antistatic Cleanroom Wipes Super Absorption Polyester Knit Wipes

Super Absorption Anti Dust Industrial Cleaning Wiper Cleanroom Wiper Wip

Applications:

Used in circuit board production line,medical device,camera lens, optics and automobiles;

Designed for cleaning medical equipments,tools in laboratory, glass, delicate surfaces and general cleaning;

Desirable for wiping in Clean room:ISO5 to ISO6(Class100 to 10,00);

Description:

Microfiber Knit wipes are made with fabric densely knitted by continuous micro denier filament. The unique structure of microfiber improves the surface contact, and provides more effective cleaning.

Key Attributes:

• 100% knitted polyester which attracts and dissipates the charge

• Sealed edge with antistatic fiber which dissipates static charges

• Laundered and packaged in ISO Class 4 cleanroom

• Lot traceability

Features:

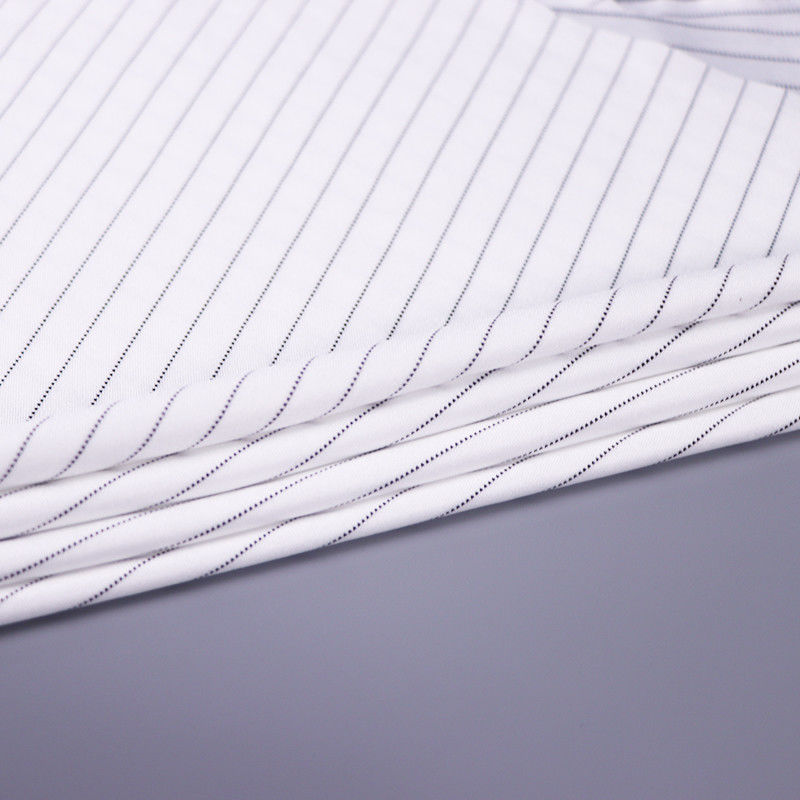

• Silk-smooth surface finish for use on even the most delicate surfaces

• Durable abrasion resistance for use when removing microcontamination from large areas and irregular surfaces

• Best-in-class fluid absorption

• Leaves a polished finish on surfaces such as stainless steel

• Available in a range of edge finishes to meet your application requirements

Benefits:

• Chemically compatible with common cleaning and disinfecting solutions

• High abrasion resistance

• Ultrasonically sealed edge for extremely low fiber release

Technical Data:

Wipe material: 75% Polyester 25% Nylon

| Attribute; (units) | Value ** | Test Method | ||||

| Basis weight; nominal (g/m2) | 228 | MSD-QI-QS-007 A0 | ||||

| Absorbency in water | IEST-RP-CC004.3 | |||||

| Intrinsic; (mL/g) | 1.62 | |||||

| Extrinsic; (mL/m2) | 369.36 | |||||

| Sorptive rate; (seconds) | 1 | IEST-RP-CC004.3 | ||||

| Non-volatile residue, NVR | IEST-RP-CC004.3 | |||||

| In deionized water; (g/m2) | 0.01 | |||||

| In isopropanol; (g/m2) | 0.03 | |||||

| Specific ions | IEST-RP-CC004.3 | |||||

| Sodium; (ppm) | 0.008 | |||||

| Chloride; (ppm) | 0.065 | |||||

| Potassium; (ppm) | 0.082 | |||||

| Particles, readily releasable | ||||||

| APC: ≥0.3μm(Ea/ft3) | 49 | IEST-RP-CC003.3 | ||||

| LPC:≥0.5μm(106/m2 ) | 18 | IEST-RP-CC004.3 | ||||

Cleanroom Environment:

• ISO Class 3 – 8

• Class 1 – 100,000

Shelf Life

• Non-Sterile (Dry) – 3 years from date of manufacture